& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Product data management (PDM) is a systematic approach to managing and controlling product-related information throughout its lifecycle. This includes data such as design specifications, CAD models, documentation, and other technical details that are important for the development and manufacturing of products.

PDM facilitates the organization, storage, and use of this data, so that all stakeholders have access to the latest and most accurate information. By centralizing product data, PDM systems help companies streamline their workflows, reduce errors, and improve collaboration across different departments.

Product data management software stores, manages, and tracks product-related information throughout its lifecycle. It acts as a central repository for all product data, including CAD files, documentation, specifications, and engineering change orders.

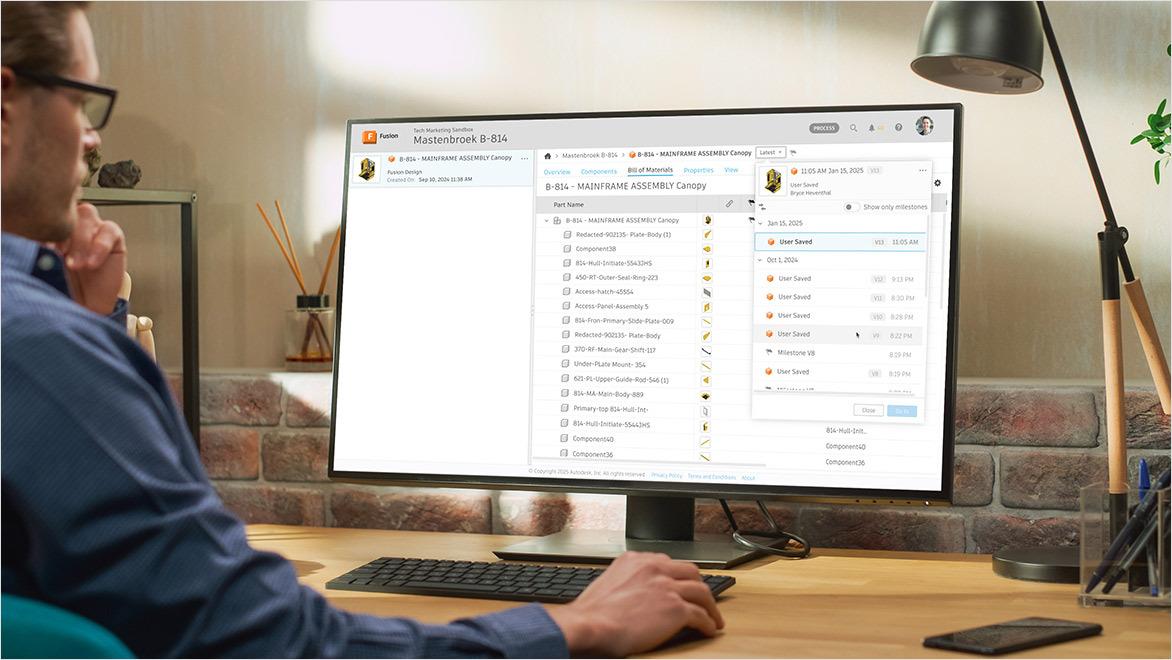

A key feature of PDM is change management. It automatically tracks changes made to product files, so that the most recent revisions are always accessible while maintaining a history of previous versions. This eliminates confusion and prevents errors caused by working with outdated or incorrect data.

PDM also improves collaboration across different departments and locations with a centralized, secure platform for storing data. Teams can collaborate more effectively, regardless of regions or time zones. This real-time collaboration speeds up the product development process, helps resolve issues quickly, and keeps everyone aligned on the project's goals.

PDM systems also integrate with other enterprise systems like ERP and PLM, making sure seamless data flows across the organization. This integration connects product data with production schedules, inventory management, and other critical business processes. As a result, better decision-making and more efficient operations across the entire product lifecycle can occur.

In manufacturing, product data management helps keep everything running smoothly. It organizes and stores all product information, including design specs, materials, and engineering changes—in one central system, making it easy for everyone involved in production to access the right data. This eliminates the chances of working with outdated or conflicting information, reduces errors, and helps teams in design, engineering, and manufacturing work together more effectively. With PDM, everyone’s on the same page, which speeds up workflows, reduces cycle times, and ultimately leads to better product quality and cost savings.

PDM enables concurrent design creation from one central location, with safe, simultaneous access to data across multiple teams and departments.

Create and maintain an accurate and comprehensive manufacturing bill of materials. Automate centralized product data in one BOM so that stakeholders have access to the data they need in real time.

PDM helps save time and increase development agility with design automation, and the ability to copy designs and reuse, replace, or copy components.

Streamline the management of engineering change orders (ECOs) with a user-friendly workflow. Maintain control over revisions to designs, items, and records, with enterprise-wide visibility and traceability.

PDM provides a centralized platform where teams can easily access, share, and update product information in real-time. Work with the most up-to-date data, improve decision-making, reduce errors, and enhance teamwork.

Streamline collaboration and productivity by using APIs with other business systems such as PLM and ERP. Connecting PDM with enterprise systems reduces time-consuming manual entry, increases data reuse, and provides valuable business insights.

Implementing PDM offers numerous benefits to organizations, inlcuding:

PDM software boosts cross-functional collaboration by centralizing data for easy access across teams, both inside and outside your organization. With modern communication, review, and markup tools, it enables efficient collaboration, accessible anytime, anywhere, on any device.

Quickly adapt to market changes by seamlessly switching between design and manufacturing processes. Automation and easy data access reduce complexity, leading to faster responses, and fewer errors as your business grows.

Centralized design and manufacturing data provides clear visibility and instant notifications to all departments when changes occur. Everyone stays informed and the risk of defects and non-conformities is reduced.

Expedite decision-making processes with concurrent team workflows so that you can meet market demands more efficiently and bring your products to market faster.

Cloud PDM offers lower initial costs, scalability, and easy access from anywhere. This makes it a great solution for businesses with remote teams or multiple locations. There’s no need for expensive hardware or IT infrastructure, and providers handle maintenance, updates, and backups. Cloud PDM fosters real-time collaboration, allowing teams to work together seamlessly across the globe.

Autodesk Fusion is a cloud-based product development solution with built-in PDM along with CAD, CAM, CAE, and PCB capabilities. It delivers data management integrated into team workflows from the start. No need for disparate tools and complex setups.

On-premise PDM gives organizations full control over their data, security, and system customization. While it requires an upfront investment in hardware and software, it doesn't rely on internet access. It enables efficient data organization, version control, and collaboration across engineering teams.

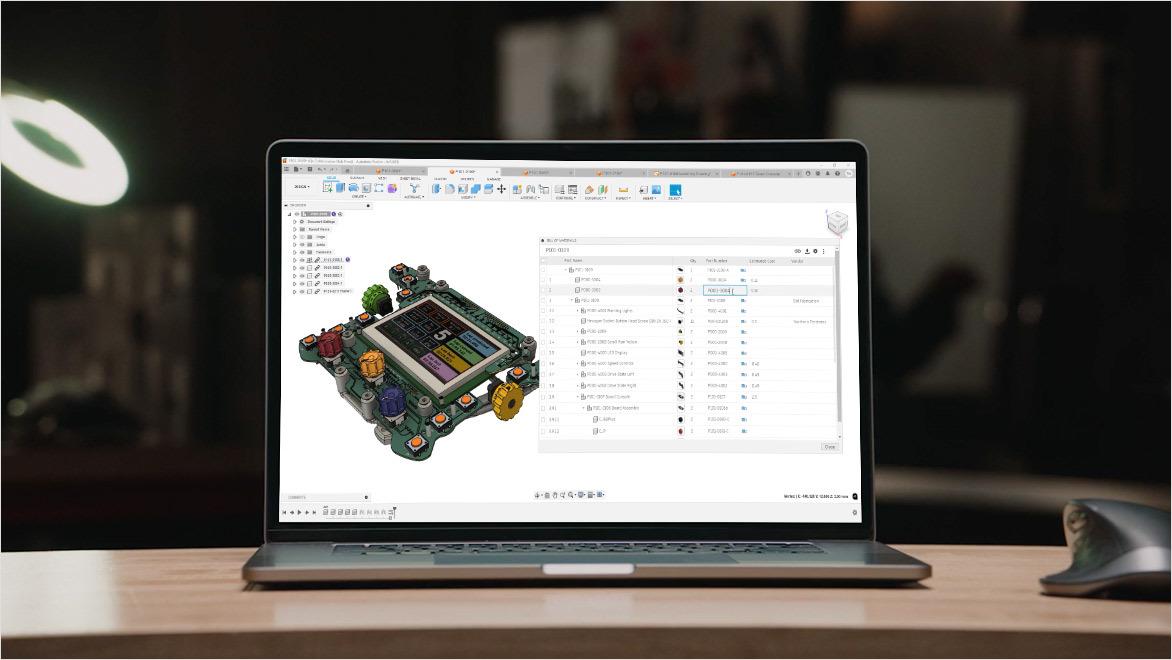

Autodesk Vault is an on-premise PDM solution that integrates with Autodesk design tools and other CAD systems to keep everyone working from a central source of organized data. Team members have access to the latest information and streamlined workflows for productivity.

In the early 1980s, CAD software began to allowed engineers to create digital representations of products, reducing the need for manual drafting. While these early systems didn't offer integrated data management, PDM began to emerge as a way to manage digital files associated with product designs.

By the late 80s and early 90s, the need for more sophisticated PDM systems became apparent. Early PDM systems began to focus on version control, document management, and file storage and ran on standalone computers or local networks.

As products continued to become more comples and organizations expanded globally, PDM began to integrate with ERP and PLM systems. Key advancements during this time, included centralized databases, support for collaborative workflows, integration with other enterprise systems, and support for global teams.

With the rise of cloud computing and digital technologies, cloud PDM emerged offering lower infrastructure costs, scalability, and real-time collaboration. As part of digital transformation, organizations can manage data across the entire product lifecycle.

PLM and PDM are necessities for efficient product development and manufacturing, however they serve different purposes and are typically used by different groups within an organization to complement each other.

PLM covers all stages of a product’s journey. It offers a range of tools to manage key product-related processes, including project management, supply chain coordination, compliance, and quality control. PLM brings together data from different departments and systems to offer a holistic view of the entire product lifecycle. It's used by a variety of roles, including product managers, engineers, supply chain professionals, and executives, all working together to optimize the product's development and performance.

PDM organizes and manages data tied to product design, such as CAD files, drawings, and documents. PDM offers version control, data security, and access management to track changes accurately and efficiently. It's primarily used by engineering and design teams and helps streamline collaboration to make data management easier and more effective.

Product data management (PDM) software is used widely across various industries due to its ability to manage data and streamline product development workflows. Here are some of the primary industries that benefit from PDM:

PDM systems help consumer product companies manage the large volume of product data that comes with product design, development, and manufacturing.

PDM helps automotive manufacturers track parts, components, and assemblies across different vehicle models and manage supplier relationships. It also aids in adhering to safety and environmental regulations.

The aerospace industry relies on PDM for managing intricate design files, regulatory compliance documentation, and component traceability.

Industrial equipment manufacturers use PDM to organize complex product structures, manage CAD models, BOMs, and track product revisions to make sure that production processes run smoothly.

PDM systems aid in managing strict documentation requirements, such as FDA approvals, compliance with regulatory standards, and traceability of components.

PDM helps in managing building designs, engineering drawings, and documentation throughout construction projects. This allows for better coordination and an organized database for renovations and expansions.

While PDM offers significant benefits, it does have some factors to consider. The initial cost and process changes involved with implementing a PDM system need to be taken into account to allow for proper planning and budgeting. The integration of PDM with existing systems, like ERP or CRM, can also require specialized expertise and take time. PDM systems rely on structured data, which may be a limitation where organizations are not accustomed to digital processes helping with managing design feedback or simulation results. Lastly, the PDM system should be user-friendly and intuitive, minimizing the learning curve for users and improving overall productivity.

PDM plays a critical role in connecting product development data and processes, helping organizations maintain a digital thread . Here are benefits of PDM in the digital thread:

PDM provides a single source of truth for all product-related information, making sure that data is consistently available and accessible across the entire digital thread.

By capturing and documenting every change and decision throughout the product lifecycle, PDM provides complete traceability, helping stakeholders to track the evolution of a product from conception to retirement.

PDM enhances cross-functional collaboration by allowing real-time sharing of information among teams, departments, and external partners, promoting improved communication and teamwork.

PDM will likely become more deeply integrated with other enterprise systems and digital tools. This will result in faster product development cycles, enhanced collaboration, and smarter decision-making. Advanced technologies like the Internet of things (IoT), augmented reality (AR), artificial intelligence (AI), and blockchain are expected to influence PDM by enabling real-time data exchange, providing advanced analytics, and enhancing the security of product data management.

PDM plays an important part in sustainability. It helps companies use resources more efficiently and reduce waste throughout the product lifecycle. Teams can track materials, energy use, and manufacturing processes to minimize waste and make more eco-friendly decisions. PDM helps manufacturers choose sustainable materials and energy-efficient designs. It also supports lifecycle analysis, so companies can evaluate the environmental impact of their products. When integrated with supply chain and ERP systems, PDM helps businesses make better choices about sourcing, logistics, and cutting emissions. PDM also helps companies stay compliant with environmental regulations by keeping accurate records of materials and processes.

PDM stands for product data management. PDM software solutions help organizations manage and track product-related data throughout the product lifecycle. This includes everything from design files, documents, and specifications to revision history, change management, and collaboration among teams. PDM systems make sure that product information is organized, secure, and easily accessible to the right people at the right time, improving efficiency, reducing errors, and enhancing decision-making in product development.

A product data management solution is designed to organize, track, and manage product-related data throughout its lifecycle. Key components of a PDM system include:

Data storage and organization: A centralized repository where product data is stored, organized with folder structures and metadata for easy retrieval.

Version and revision control: Tracks different versions and revisions of product data, making sure that the latest version is available and previous ones are archived.

BOM management: Create, manage, and track BOMs, so that all parts and materials needed for manufacturing are accurately documented.

Workflow and process management: Automates approval workflows and change management for smooth communication and timely approvals of design changes.

Collaboration tools: Facilitates multi-user access and real-time collaboration across teams, resulting in efficient communication and data sharing.

Security and access control: Manages user permissions and provides audit trails to maintain data security and compliance.

Search: Offers powerful search tools to quickly locate product data based on metadata, part numbers, or keywords.

System integration: Integrates with ERP, PLM, and CAD systems, enabling seamless data flow between different departments and systems.

Reporting and analytics: Provides customizable reports and analytics to track product development progress, monitor KPIs, and identify bottlenecks.

These components together streamline product development, improve collaboration, maintain data integrity, and provide efficient product lifecycle management.

A PDM system manages product data across its lifecycle by centralizing and organizing all design-related information, including CAD files, documents, and revisions, in one secure location. It tracks changes and updates throughout the product's development, from concept to design, manufacturing, and end-of-life. The latest data is always accessible, maintains version control, and supports approval workflows, enabling efficient collaboration and compliance management at every stage of the product lifecycle.

A PDM system helps with regulatory compliance by making sure that all product data is accurately tracked, documented, and stored in a controlled environment, meeting industry standards, and legal requirements. It provides tools for managing change requests, revisions, and approvals in a traceable manner, offering a clear audit trail of who made changes and when. PDM systems also store regulatory documents, certifications, and test data, making it easier to demonstrate compliance during audits.

The top six features of a product data management (PDM) system are:

1. Version control and revision management: PDM systems allow teams to track and manage multiple versions of design files and documents, making sure that everyone is working with the most up-to-date version. This feature also helps maintain a history of revisions, so teams can trace changes and revert to previous versions if needed.

2. Bill of materials (BOM) management: PDM systems streamline the creation and management of BOMs, which list all the components, parts, and materials required for a product. The BOM is always up to date, accurately reflects design changes, and can be easily shared across departments and with suppliers.

3. Access control and security: PDM provides role-based access control so that only authorized users can view, modify, or approve certain data. This feature enhances data security and compliance by protecting sensitive design information and documents from unauthorized access or changes.

4. Collaboration and workflow management: PDM systems facilitate seamless collaboration among cross-functional teams, regardless of their location. Workflow management tools help streamline approval processes, track progress, so that all stakeholders are aligned, leading to more efficient, and transparent product development.

5. Centralized data storage: PDM systems offer a centralized repository for storing all product-related data, including CAD models, design documents, and specifications. Everyone has access to the latest information and prevents issues with outdated or misplaced files.

6. Change management: Change management features help teams control and track engineering change orders (ECOs), ensuring that design modifications are documented, approved, and implemented in a structured manner. This minimizes errors, reduces rework, and ensures that changes are effectively communicated across teams.

Yes, Autodesk offers PDM solutions, through Autodesk Fusion and Autodesk Vault. Fusion is an integrated design, engineering, and manufacturing platform that includes built-in product data management (PDM) capabilities. It combines CAD, CAM, CAE, and PDM in one cloud-based platform, enabling teams to collaborate efficiently and manage product data throughout the entire lifecycle. Fusion's PDM features include version control, access management, centralized data storage, and BOM management, which streamline workflows and improve collaboration across different teams.

Additionally, Autodesk also provides Vault, an on-site PDM solution for managing design data and documents, which integrates with other Autodesk software like AutoCAD and Inventor.